Business process improvement (BPI) sounds fancy, but really just means making your company run more efficiently.

“It’s all about looking at business processes and asking, ‘Hey, is there a smarter way or a more efficient way to do this?’ ” Whether your team is responsible for processing work, serving customers, or maintaining internal systems, process improvement methodologies can cut clutter, save time, and increase productivity.

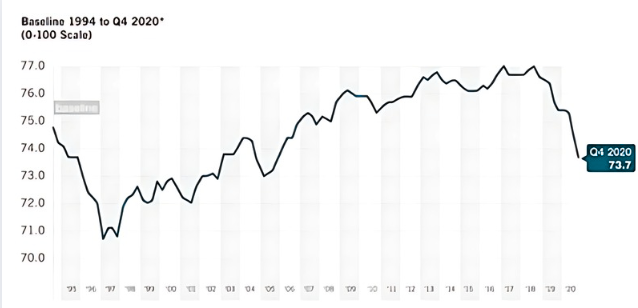

Why does this matter? That being said, dated tools can quietly keep your team from moving forward. In today’s fast-paced culture, the capacity to adjust and perform on the fly is a serious advantage. Companies prioritizing BPI aren’t just better organized, they grow faster and make better decisions.

In this guide, I’ll explain BPI and why it matters and show you how to get it right, one step at a time. From identifying weak spots to optimizing workflows, you’ll learn everything you need to make real progress.

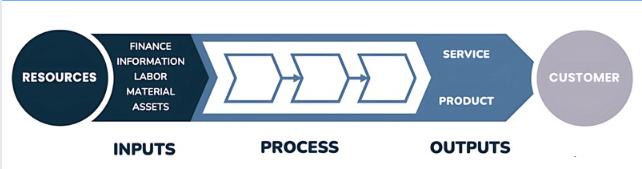

What is a Business Process?

Before we get started fixing anything, let’s be clear on what we’re working with. A business process is essentially a more convoluted way of saying “a series of steps your team follows to complete a task,” whether that task is processing your monthly credit card bill, onboarding a new employee, or onboarding a new customer.

At the heart of this is workflow – essentially, how work moves from beginning to end. Think of me as the behind-the-scenes engine that powers your business.

Types of Business Processes

Not all business processes are equally important. Three broad categories contain the majority:

- Operational processes – These are your day-to-day work that you can pay someone else to do, i.e., work that you cannot spend recklessly for 48 hours. They’re your business’s “thing,” like shipping goods, managing your sales cycle, or providing services.

- Management processes – These are what you use to manage your operations. Consider strategies for improvement as you would planning or budgeting.

- Supporting processes – These are not money-making activities themselves, but they keep revenue-generating activities, such as HR, IT, or accounting, in action.

Each kind plays a special role in making your business tick… and they all do matter when we discuss process improvement strategies.

What Makes a Good Business Process?

A solid business process should be:

- Clear – Everyone knows the steps and who’s responsible for what.

- Repeatable – It can be done consistently with the same results.

- Efficient – It uses time and resources wisely.

- Trackable – You can measure how well it’s working.

When considering a process, these characteristics help you establish whether it works or needs improvement.

Who’s Responsible for It?

That’s where process owners come in. These are the people who hold the responsibility for ensuring that a process is in place, that it is refreshed as necessary, and that everything is tweaked and enhanced over time. They’re kind of the go-to for that workflow, and they have a big part to play in any of those successful process improvement strategies.

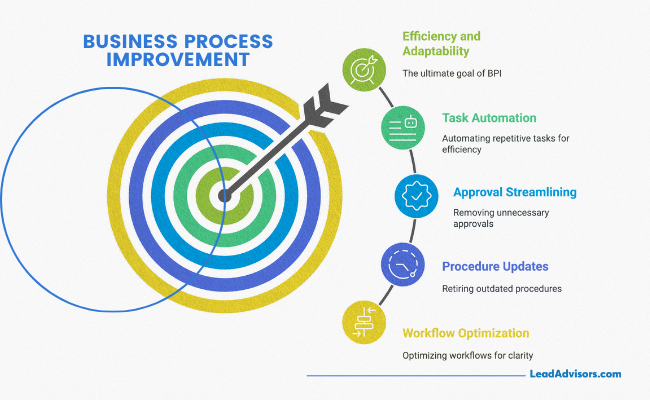

What is Business Process Improvement?

Therefore, you might be wondering what BPI is. At its heart, it is about process improvement for your business. We’re talking about increasing efficiency, boosting effectiveness, and being agile so that your team can adjust rapidly when things change.

The primary objective is to figure out what’s slowing some of you down or causing errors and then take steps to fix it. Whether that means automating vendor emails, eliminating unnecessary approvals, or just stopping an old way of doing business that no longer makes sense, it’s all process improvement techniques.

BPI vs. BPM vs. BPA

| Term | What It Stands For | What It Means |

| BPI | Business Process Improvement | This strategy enhances existing business processes to be better, more efficient, effective, and agile. |

| BPM | Business Process Management | The overall approach or framework used to manage, monitor, and continually improve your business processes. |

| BPA | Business Process Automation | Using technology to automate tasks and workflows, such as auto-approvals, emails, or data entry. |

They’re all related, but BPI is the starting point for determining what needs improvement.

When Should You Consider Process Improvement?

Honestly, there are a few obvious indicators that you’ve outgrown making your pots of pickles. If you are experiencing delays, rework, high costs, or unhappy customers, then it’s time. But things can always be a little bit better, even if they seem to be fine as is.

Perhaps your team is mired in manual work, customer feedback keeps surfacing the same issues repeatedly, or your systems haven’t been able to grow with your business. These are all good indicators that process improvement could have a significant impact.

Why BPI is Totally Worth It

Done right, business process improvement brings some big-time benefits:

- Higher productivity – Less time wasted on unnecessary steps.

- Better quality – Fewer errors and more consistent results.

- Lower costs – Efficiency saves money (and headaches).

- Stronger compliance – Easier tracking means fewer risks.

- Improved customer satisfaction – Since better service comes from streamlined processes.

When your workflows are tight and your team knows exactly what to do, everyone wins.

Common Signs You Need BPI

Are you unsure whether your processes need fixing? Let’s examine some typical workplace headaches and how some business process improvements can improve them.

Problem: Tasks Keep Getting Stuck

Solution: BPI can help you pinpoint bottlenecks so that you can redesign the workflow and keep things chugging along. Whether it is approvals, handoffs, or wait times, you’re not left guessing where the bottleneck is.

Problem: Teams Are Repeating Work or Making Mistakes

Solution: Clearer steps, smarter tools, and knowledge drive process improvement, reducing errors and rework. That’s less double-checking and more doing it right the first time.

Problem: Morale and Customer Satisfaction Are Dropping

Solution: Break processes that upset both the employee and the customer. Making things work better through BPI helps make for a better experience on both ends, enhancing team morale and customer satisfaction.

Problem: You’re Spending More Than You Should

Solution: When processes aren’t efficient, costs slowly climb. BPI helps you identify where money (and time) is being squandered, so you can eliminate expenses without sacrificing quality.

Problem: No One Knows Who’s Responsible

Solution: A well-documented process ensures clear ownership. No more “Who is in charge of this?” or “Where did this task go?” – just accountability and visibility that actually works.

If any of those are familiar, it may be time to step back and see how business process improvement can help straighten things out.

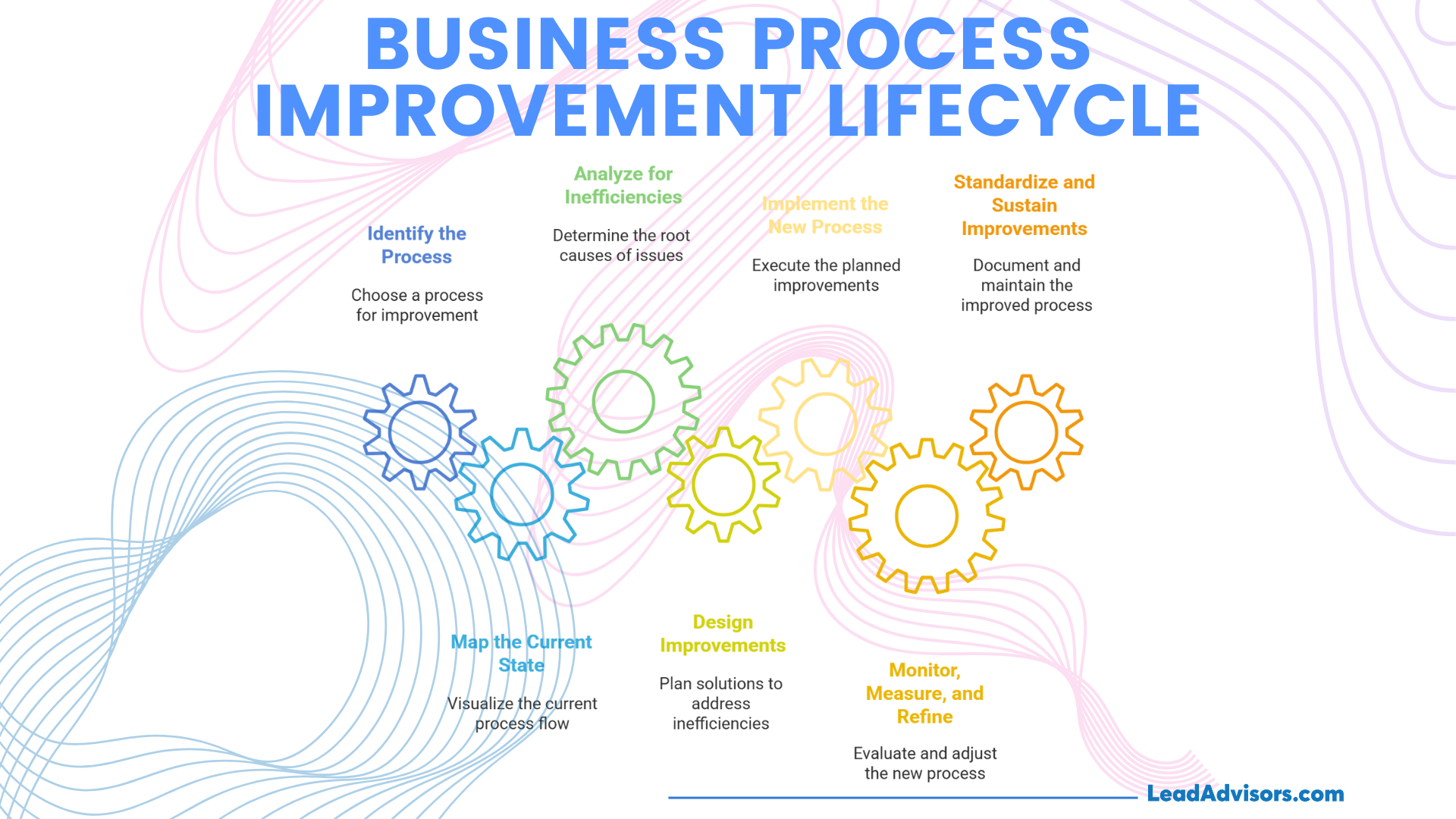

The Business Process Improvement Lifecycle

Making your business run better doesn’t happen overnight – and it’s certainly not a one-and-done proposition. That’s why employing a structured lifecycle for business process improvement (BPI) can be so instrumental. It helps you keep things straight (pun intended), clear, and – most importantly – practical.

Here is how the entire BPI lifecycle usually unfolds:

Step 1: Identify the Process

All betterment begins with the right process. Find the pain points: these are the kinds of things that give you headaches – things like chronic problems, high costs, complaints, and frustration. Whether it’s the way you manage customer service tickets or process sales invoices, begin with a clear focus. You don’t have to fix everything at once – instead, choose the process with the largest impact first.

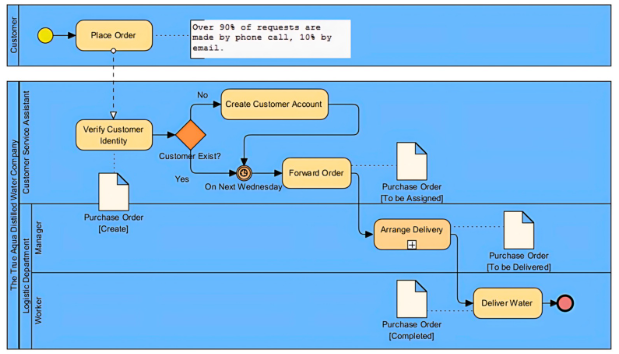

Step 2: Map the Current State

To repair a process, you must first understand how it works. This is where process mapping comes in. It can help visually lay everything out with tools like a flowchart, swimlane diagrams, or a SIPOC model. Just by watching the process visually, you will often see wasted steps, unclear handoffs, or duplicate efforts. It helps you establish a strong foundation for improving processes.

Step 3: Analyze for Inefficiencies

With the process now mapped, we can determine what’s broken – and why. Here is where the root cause analysis tools fit in. To explore real problems, you might apply the 5 Whys technique, fishbone diagrams, or even HP’s own RCA methodology. Don’t just put a band-aid on the symptoms – dig deeper and solve the root issue.

Step 4: Design Improvements

With the problem clear, it’s time to plan the solution. Think about how you can redesign the process to be faster, smoother, and more manageable. This might involve automating repetitive tasks, cutting unnecessary steps, or reassigning roles. The goal here is to build a new version of the process that’s smarter and actually solves the issues you identified.

Step 5: Implement the New Process

Rolling out changes involves most of the heavy lifting. You’ll need a robust communication and change management strategy. Ensure everyone affected knows what’s changing and why. Offer them the requisite training, support, and documentation. Include individuals who use the process daily – they frequently have the best insights and feedback.

Step 6: Monitor, Measure, and Refine

Just because something is “live” doesn’t mean it’s infallible. This is the stage where you test that your enhancements are working. Monitor your key performance indicators (KPI), establish dashboards, and seek feedback from your team. If it’s still not quite right, don’t be shy about tweaking and refining. And this is where the constant improvement finally comes to life.

Step 7: Standardize and Sustain Improvements

After the new process is operating well, it’s time to cement it. Simply document the modified workflow, update training guides, and make it the new standard. This keeps everyone aligned and helps ensure the gains stay in place over the long run. It’s also the basis upon which a culture of continuous improvement can be built, where optimising processes becomes second nature.

Popular Business Process Improvement Methodologies

Once you realize something in your workflow has to change, the issue is how. There’s no shortage of business process improvement methodologies out there – some are simple, others are super detailed. I’ve seen teams get value from both depending on circumstances.

Take a look at some of the most common methods people are using and what you get from them.

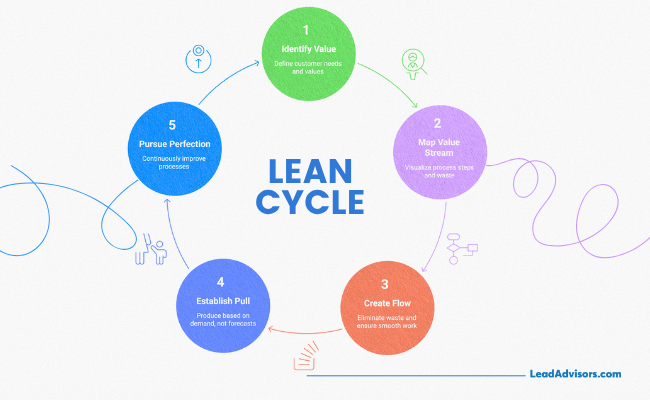

Lean

Lean is all about eliminating waste – any activity, step, or action that doesn’t add value for the customer. This is fantastic when your processes look too fat, slow, or require unnecessary approvals or paperwork.

- Use Case: Ideal for operations and logistics or service workflows that require speed and efficiency.

- Tools: Value stream mapping, 5S, standard work instructions, and visual boards.

- Goal: Enhance flow, reduce clutter, and deliver more with fewer resources.

Six Sigma

Six Sigma has a more technical emphasis and aims to reduce errors or variability in a process. It’s extremely data-driven and great when precision matters.

- Use Case: It’s used extensively in manufacturing, finance, healthcare, and basically anywhere else you need very accurate results.

- Frameworks:

- DMAIC (Define, Measure, Analyze, Improve, Control) – for improving existing processes.

- DMADV (Define, Measure, Analyze, Design, Verify) – for designing brand-new processes.

- Tools: Control charts, statistical analysis, histograms, regression, and root cause analysis.

- Bonus: Aligns well with performance-driven environments and measurable KPIs.

Lean Six Sigma

This combination strategy mixes Lean’s focus on speed and waste reduction with Six Sigma’s focus on quality and consistency.

- Use Case: Ideal for organizations looking for quicker, leaner processes without compromising accuracy.

- Tools: DMAIC framework, value stream mapping, Kaizen events, and error-proofing tools (like poka-yoke).

- Why it works: It balances process speed with measurable quality control.

Kaizen (Continuous Improvement)

Kaizen is a state of mind more than a framework. It has to do with making minor improvements each day that, over time, become the fabric of a culture of continuous improvement.

- Use Case: Perfect for teams who want to empower employees to suggest and test changes regularly.

- Tools: Team brainstorming sessions, visual tracking boards, and checklists.

- Bonus: Builds engagement and ownership at all levels of the organization.

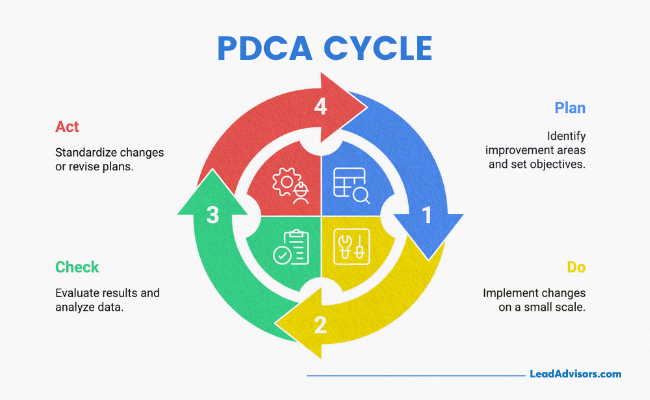

PDCA (Plan-Do-Check-Act)

The PDCA cycle is a consistent model for cautiously trying out improvements before a full-scale commitment is made. You plan the change you will make, test it, reflect on how it went, and then either adopt or revise the shift.

- Use Case: Works well for smaller teams, pilot projects, or early-stage improvements.

- Tools: Dashboards, before-and-after metrics, and process maps.

- Strength: Encourages safe experimentation and fine-tuning.

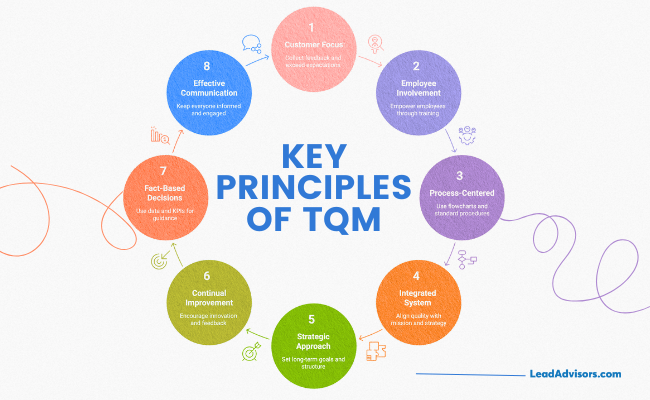

Total Quality Management (TQM)

Total Quality Management (TQM) places quality at the centre of everything. This is about getting every person across all levels of business brought into improvement.

- Use Case: Best for long-term company-wide transformations, especially in service and production sectors.

- Tools: Quality circles, customer feedback loops, benchmarking, and training systems.

- Goal: Build high-quality outcomes by embedding continuous improvement into your culture.

Theory of Constraints

This approach focuses on a single bottleneck (the “constraint”), which is found to be the crucial one that determines performance and is improved before addressing the following weakest link.

- Use Case: Ideal for supply chains, production lines, and any process that suffers from recurring slowdowns.

- Tools: Throughput analysis, constraint identification, and buffer management.

- Why it’s useful: You get fast wins by fixing the weakest part of the system first.

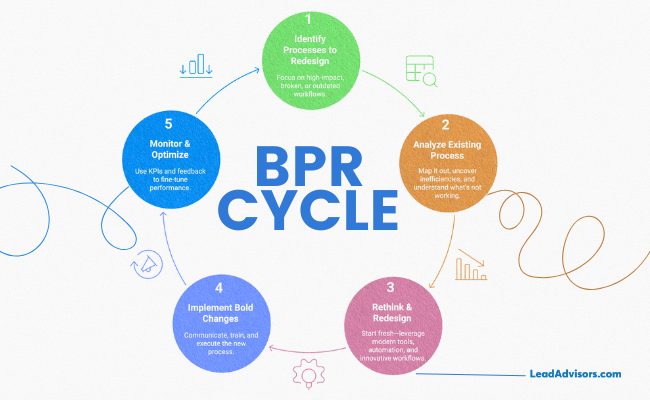

Business Process Reengineering (BPR)

Sometimes a process has become so antiquated or unwieldy that it’s preferable to wipe the slate clean. That’s where business process reengineering (BPR) has its role.

- Use Case: Major redesigns – like digitizing paper-based systems or merging outdated workflows across departments.

- Tools: End-to-end workflow redesign, process simulation, and automation tools.

- Big Picture: It’s bold, disruptive, and sometimes exactly what a business needs.

Agile

Agile began in software development but is now employed across all types of teams. Its values include flexibility, collaboration, and rapid time-to-value.

- Use Case: Project-based work, creative teams, or fast-moving environments.

- Tools: Scrum, Kanban boards, retrospectives, daily standups.

- Why it’s loved: It allows teams to adapt quickly and continuously improve processes in real time.

Balanced Scorecard

The Balanced Scorecard enables you to tie process improvements to the big-picture targets. It monitors performance in four categories: Financial, Customer, Internal Processes, and Learning & Growth.

- Use Case: Strategic planning, executive dashboards, and performance measurement.

- Tools: Key performance indicators (KPIs), quarterly reviews, and visual reports.

- Strength: Connects daily operations to strategic business growth.

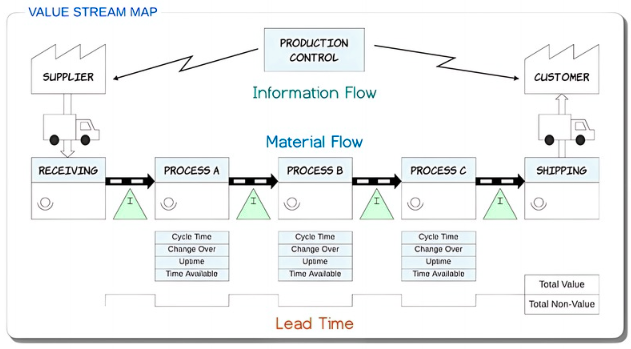

Value Stream Mapping

This Lean tool provides a complete visual representation of each stage in a process, allowing you to identify areas where time, money, or effort is being needlessly spent.

- Use Case: Production, logistics, service delivery, or any end-to-end system.

- Tools: Current-state/future-state maps, cycle time analysis.

- Why use it: It uncovers hidden delays and shows exactly where to focus your process improvement efforts.

5S and 5 Whys

These are two basic ones that are used by many methods. 5S is a method of organizing physical and digital workspaces for greater efficiency. 5 Whys goes beyond the symptoms and helps to identify the root cause of the problem.

- Use Case: Lean projects, onboarding new staff, and solving recurring issues.

- Tools: Labeling systems, visual boards, RCA worksheets.

- Strength: Super simple and surprisingly effective.

BPM and BPMN

BPM provides the framework for managing and refining complex processes over time. BPMN (Business Process Model and Notation) is a standard visual language for clearly mapping them.

- Use Case: Enterprise-level systems, compliance-heavy industries, or businesses with many moving parts.

- Tools: BPM platforms (like Bizagi or Kissflow), BPMN diagram tools.

- Why it’s powerful: It helps standardize and optimize processes across teams or even global offices.

BPM provides the framework for managing and refining complex processes over time. BPMN (Business Process Model and Notation) is a standard visual language for clearly mapping them.

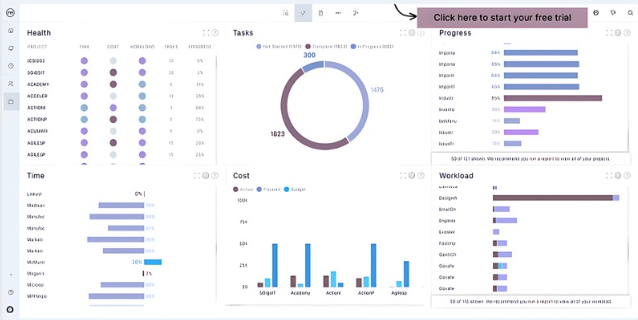

Tools & Technologies That Enable BPI

| Tool Category | Examples | What It Does / Why It Matters |

| Process Mapping Software | Lucidchart, Microsoft Visio, Bizagi | It helps visualize business processes, spotting bottlenecks and inefficiencies. It is ideal for flowcharts, SIPOC diagrams, and swimlane mapping. |

| KPI & Dashboard Tools | Power BI, ProjectManager, Tableau | Tracks key performance indicators (KPIs) and performance metrics in real time. Offers clear visibility into success and areas for process improvement. |

| Low-Code / No-Code Automation | Zapier, Airtable, Nintex, Appian | Automates workflows without coding. Great for teams wanting quick solutions without relying heavily on IT. |

| Robotic Process Automation (RPA) | UiPath, Automation Anywhere, Blue Prism | Automates repetitive tasks like data entry and reporting. Reduces human error and improves speed. Supports eliminating inefficiencies. |

| Intelligent Automation (AI/ML, OCR) | IBM Watson, Power Automate AI Builder, Abbyy FlexiCapture | Uses AI to read, learn, and make decisions. Perfect for handling unstructured data, invoices, forms, and smart document processing. |

| Learning Management Systems (LMS) | TalentLMS, Docebo, Moodle | Provides scalable training during BPI rollouts. Encourages employee engagement and faster adoption of new processes. |

| Workflow & Task Management Tools | Asana, Jira, Monday.com, ClickUp | Helps teams stay organized when improving processes. Ensures task accountability and smooth project execution. |

Real-World Business Process Improvement Examples

Let’s be honest, speaking about changes in theory can be helpful, but looking at life after BPI in business? That’s where it clicks. Below are some quick snapshots of how multiple companies in different sectors handled messy workflows and turned them into wins.

1. Preventing Shipping Errors (Wholesale)

Problem: A wholesale distributor repeatedly sent incorrect orders because an employee made manual data entries, and the fulfillment process was not transparent.

Solution: They implemented barcode scanning, automatic label printing, and a defined picking process.

Result: Shipping errors reduced by 85%, customer complaints decreased, and warehouse teams saved hours weekly on rework.

2. Streamlining Claims Adjudication (Insurance)

Problem: The process of settling claims at an insurance company was taking weeks and involved too many handoffs between departments.

Solution: They applied workflow automation and AI-based document scanning to overhaul their entire adjudication process.

Result: The claims were handled 60% faster, the accuracy was much higher, and the staff had more time to devote to complicated cases.

3. Automating Workers’ Comp Workflows (Healthcare)

Problem: Healthcare Providers were drowning in paperwork for workers’ comp claims, leading to delays and potential compliance issues.

Solution: They leveraged Robotic Process Automation (RPA) to manage populating, routing, and status tracking of forms.

Result: Claims turnaround time was cut from days to hours, and compliance errors were slashed by more than 70%.

4. Improving Inventory Visibility (R&D Food Company)

Problem: An R&D food company had no real-time view into its raw material inventory, resulting in spoilage and production stoppages.

Solution: They implemented cloud-based inventory tracking that was linked to purchasing and lab systems.

Result: Material waste fell 40%, production delays declined, and employees understood stock levels and usage patterns.

5. Enhancing Safety Checks (Aviation)

Problem: One leading airline used paper-based safety-inspection logs, which were both easy to miss steps and hard to track compliance.

Solution: They digitized the process with tablets and checklist apps and integrated it with a central audit system.

Result: Safety compliance improved by 98%, with fewer missed checks and a faster sign-off process.

Bonus: Reducing Cycle Time from 59 Days to 59 Minutes (Insurance)

Problem: A top insurance company took almost two months to process a single customer onboarding cycle automatically.

Solution: They rebuilt the workflow, using process mapping, intelligent automation, and connecting backend systems with a user-friendly dashboard.

Result: The entire cycle was shortened from 59 days to only 59 minutes, a shortcut that skipped no steps and omitted no approvals.

Whether it’s making work safer, automating a process, or eliminating a huge bottleneck, these are great examples of how the right process improvement plan can drive big results, really fast.

Challenges in Implementing BPI (and How to Overcome Them)

Let’s face it – business process improvement sounds great in theory, but how do you actually make it a reality? Here is where material and loyalties get tested. Even the most brilliant ideas I’ve seen sputter when teams get stuck. The good news? This is a universal struggle, and you can definitely get over it with the right spirit and attitude.

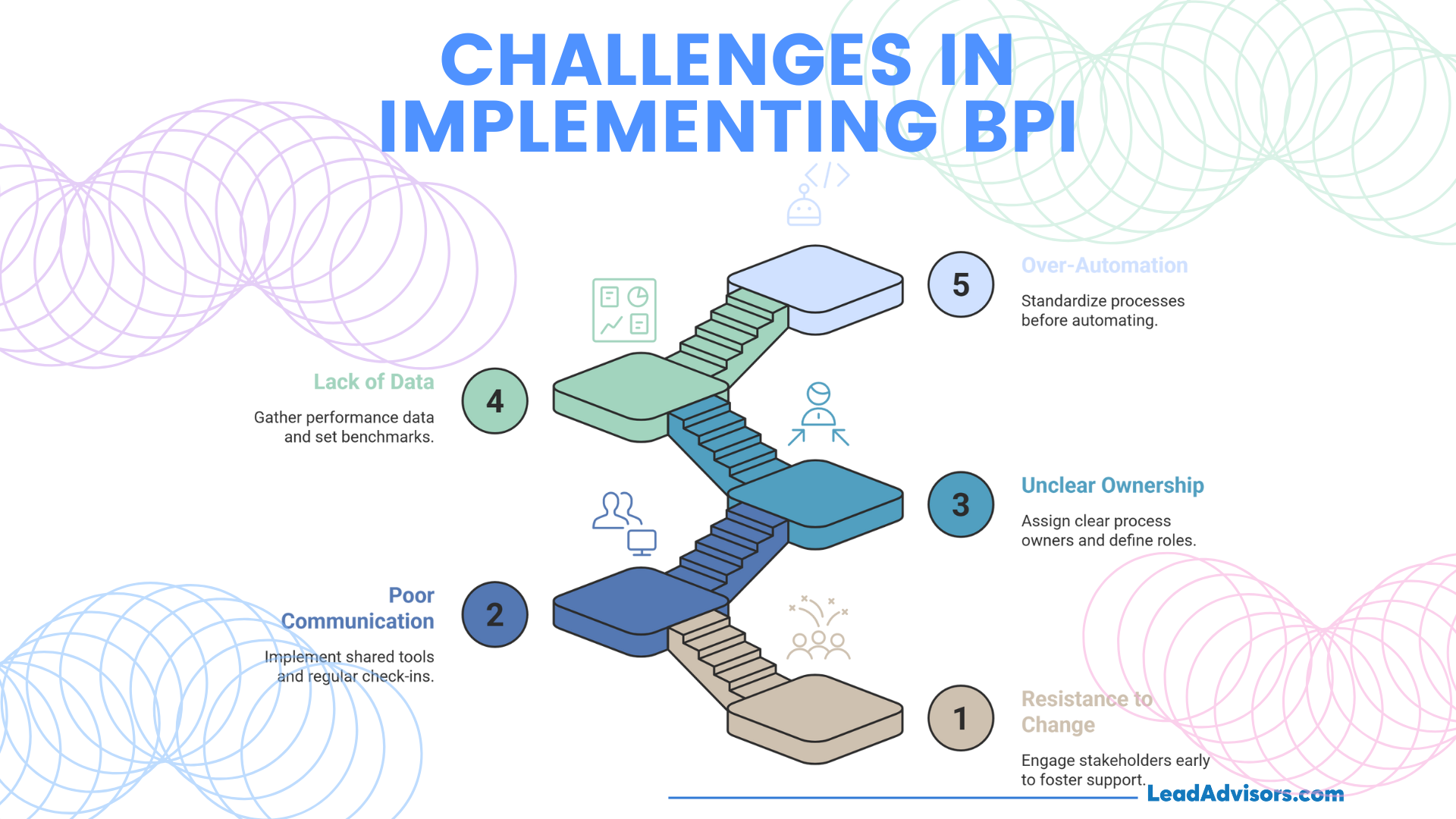

1. Resistance to Change

You introduce a new process, and suddenly, everyone seems… skeptical. Change is a difficult pill for most people to swallow, particularly if they’ve been doing something the same way for years.

How to overcome it:

Get people involved early. Enlist their assistance in creating the new process and let them know why the change is important. If people know they’re being heard and understand the “because,” they’re way more likely to support the “how.” Establish a culture of continuous improvement instead of just throwing new systems at them.

Sharing motivational business quotes during team rollouts can also help foster positivity and openness to new ideas.

2. Poor Communication and Collaboration

Your process improvement initiatives can stall before they even begin if disparate departments cannot speak with one voice or, worse, work against each other.

How to overcome it:

Overcommunicate. Utilize shared tools such as dashboards, wikis, and task managers (Asana, Monday.com, etc.) so that everyone sees the same updates. Regular check-ins will help build trust and ensure that silos don’t sap your efforts.

3. Unclear Ownership or Accountability

Without anyone accountable for the process – or too many people responsible for it – things go downhill in a hurry. Things also fall through the cracks, and no one wants to take the blame when something breaks.

How to overcome it:

Accountability should be crystal clear for every initiative. Document your roles and responsibilities. It’s also a good idea to link ownership to performance metrics using a structured performance review template so that accountability is measurable and tangible.

4. Lack of Data or Performance Benchmarks

It’s challenging to make something better if you can’t measure it. Without baseline metrics, you won’t be able to tell whether your efforts are working or only complicating the matter further.

How to overcome it:

Begin by collecting crude, rudimentary performance data. Use KPIs, customer feedback, and cycle times as a base. Tools such as Power BI or even a shared Google Sheet can help you track and iterate over time.

5. Over-Automation Without Standardization

It’s tempting to throw automation at every problem. But if you optimize existing processes, automating them can simply make the mess more efficient.

How to overcome it:

Standardize before attempting to automate. Map the process out, find what works, and then bring on the automation tools. It’s not a question of automating all people out of existence – instead, it’s about providing them with cleaner, more standardized processes.

Change comes with obstacles, of course, but with some preparation (and a good dose of patience), those roadblocks can become launchpads toward better, smarter workflows.

Best Practices for Sustainable BPI

Optimizing a process once is a good first step, but sustaining that improvement is what truly changes a business. Whether you’re modernizing workflows, automating operations, or reimagining how teams work together, this best practice guide will help you establish a strong base for your long-term success with transforming processes.

Foster a Culture of Continuous Improvement

BPI is rarely sustainable from a single project, but sustainable BPI usually grows out of a culture of always looking for ways to do things better. Invite your team to share its ideas, no matter how little, and make room for candid feedback. When people are empowered to question and improve how work gets done, then actual, continuous process improvement begins to take hold.

Involve Cross-Functional Stakeholders Early

The top has never been a source of the best process change; the best ideas for improvement are usually on the front line. Engage cross-departmental teams early in your planning to capture real pain points and avoid bottlenecks down the line. When everyone has a seat at the table, you achieve better solutions and stronger buy-in from the beginning.

Use Data to Drive Decisions

It’s hard to know if you’re really improving anything without data. Track time savings, error rates, or customer response times with key performance indicators (KPIs). Use real data – not assumptions – to make decisions so you know your changes are working.

Start Small with Pilot Projects

Implementing a company-wide change can feel scary and risky. Instead, try a pilot project with one team or one process and test your changes. This more limited rollout allows you to learn, refine, and build momentum before increasing the scale.

Document Everything: From SOPs to Outcomes

Transparent documentation transforms a good idea into a repeatable solution. List the instructions, tasks, tools, and results as a step-by-step outline. This keeps everybody on track with what is happening and provides a convenient reference for training and auditing the process later.

Train and Retrain Consistently

A new process is only as effective as the personnel who use it. Train on the tool as you roll out and keep refresher sessions in your rotation. In a world where teams shift and roles change, continual education sustains quality and consistency.

Align Process Goals with Business Strategy

If your process doesn’t connect to a larger business goal, teams can easily lose interest or direction. Every process improvement initiative should clearly support a strategic outcome – whether that’s increasing revenue, cutting costs, or improving the customer experience through a targeted customer acquisition strategy.

This alignment keeps everyone focused and makes the impact of your efforts easier to measure and communicate.

BPI and the Future of Work: Automation, AI & Hyperautomation

Let’s face it – technology is altering how we work, not just our methods but our perspective about work. That’s why business process improvement is no longer simply about tweaking workflows – it’s about getting your organization ready to not only survive but also succeed in a world of automation, AI, and smarter systems.

BPI Sets the Foundation for Intelligent Automation

You can’t automate before you know what you should automate. BPI allows you to document current processes, identify weaknesses, and then standardize steps. So, when you are ready to bring in technology like robotic process automation (RPA) or AI-enabled assistants, you’re not trying to build on a creaky floor. It’s rather like tidying up before finally installing smart light bulbs – you get better results when the foundation is solid.

The Shift from BPI → BPA → AI-Powered Orchestration

Already, we’re witnessing businesses shift from manual BPI efforts to business process automation (BPA) and AI-powered process orchestration. It’s not just a matter of automating a few tasks anymore – it’s about systems that learn, predict, and adapt in real time. This pivot results in less micromanagement, quicker decisions, and greater ability for teams to concentrate on high-value work.

Why BPI + RPA + BPM + AI Is a Game-Changing Combo

Combined with tools like RPA, business process management (BPM) software, and artificial intelligence, BPI isn’t just getting work done faster – it’s also making it smarter. RPA takes on repetitive work, BPM maintains structure and visibility over everything, and you make data-driven decisions quickly and accurately with AI. Collectively, the technologies deliver a future-proof system that scales with your business and continues to enable the capabilities to drive performance to a new level.

The future of work isn’t just automated – it’s optimized. Incremental business process improvement is the first step in ensuring that your team is leading rather than trying to catch up to the rest of the company.

Frequently Asked Questions

How long does a typical BPI project take?

Do I need a dedicated team to manage BPI?

Can BPI be applied to creative or non-repetitive work?

How do I measure the ROI of BPI?

What’s the difference between BPI and business transformation?

Conclusion

At its essence, business process improvement (BPI) is all about helping your team work smarter, not harder. Whether you are after more efficiency, higher quality, or happier customers, BPI provides the framework to pinpoint what is broken and the solutions to fix it. This is no quick win – this is a sustainable approach that fuels actual business growth.

If you have been saying to yourself, “We need to clean this up,” now’s your opportunity to act. Start small: map a current process, run a quick workflow audit, and have a conversation with your team about what slows them down. You don’t need a full reboot to make real progress – just one step forward.